Publication: Specification of Non-Loadbearing Steel Studs

Introduction

Non-loadbearing steel studs (often called “drywall studs”) are used throughout the Canadian construction industry for interior partition walls. These members are not “structural” since they are not designed as part of the structural load carrying system of the building; however, they are required to stand up to certain internal air pressures and loads from the intended use and occupancy. Additionally, non-loadbearing studs can be an integral part of a fire-rated assembly.

Material Thicknesses

The minimum thickness of non-loadbearing steel studs is 0.455 mm (0.0179 in.) for the base steel. This is defined in the ASTM Specification C645-99, Standard Specification for Nonstructural Steel Framing Members as well as the National Building Code of Canada 1995, Part 9.

It is not uncommon to still see specifications using 25 gauge to define the thickness of the non-loadbearing steel studs. Within the construction industry there is often confusion over gauges and the related thickness. The industry is discontinuing the use of the gauge system. To make certain that the material supplied to the job site is what you wanted (for loadbearing as well as non-loadbearing products) specify the minimum thickness as a decimal number (e.g. 0.455 mm, 0.0179 in., or 18 mil).

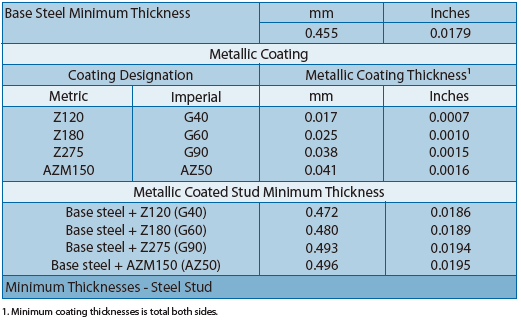

Non-loadbearing steel studs are also coated with a metallic layer of zinc (galvanized) or 55% aluminum-zinc alloy. These metallic coatings provided the necessary corrosion protection and service durability. The minimum thicknesses of typical hot-dipped metallic coatings are given in the Table below. These metallic coating thicknesses must be added to the base steel thickness to determine the delivered sheet thickness. Metallic coatings are also subject to manufacturing tolerances similar to the base steel. Therefore, the actual thickness of the metallic coating will generally be greater than the minimums listed in the Table.

Product Designators

The North American steels stud industry is adopting a standard designation system that describes the geometry of the section. This is a four-part designator that identifies the size (both depth and flange width), product type, and minimum thickness. The same designator will be used for identifying products in either Imperial or SI Metric units. The product designators are based on Imperial units and use the format illustrated by the following example:

362S125-18

where,

362 = section depth (inches/100, i.e. 3-5/8”)

S = designation for a stud or joist section (T for track, U for u-channel, F for furring channel, and L for angle)

125 = flange width (inches/100, i.e. 1-1/4”)

18 = designation thickness (mils, i.e. 0.018”)

The industry will be adopting this standard designation system in product literature replacing, or supplementing, the unique designators used by each supplier.

Conclusion

Non-loadbearing steel studs are a common product used extensively throughout building construction in Canada. Even though they may be thought of as a nonstructural element in the building, they still need to carry a certain amount of load and need to perform satisfactorily. The specifications in Canada are consistent in requiring a minimum base steel thickness of 0.455 mm (0.0179 in.) for these members.