Steel Wall Cladding – Versatility, Flexibility and Lightweight

The award-winning Commonwealth Community Recreation Centre (CCRC) is now five years old. Commissioned under the City of Edmonton’s revamped RFP process, the choice of steel for the superstructure and cladding was key in delivering the design excellence and project efficiency called for by Edmonton’s civic revitalization mandate.

The LEED Silver building resulted from a joint-use partnership between the City of Edmonton and the Edmonton Eskimos Football Club.

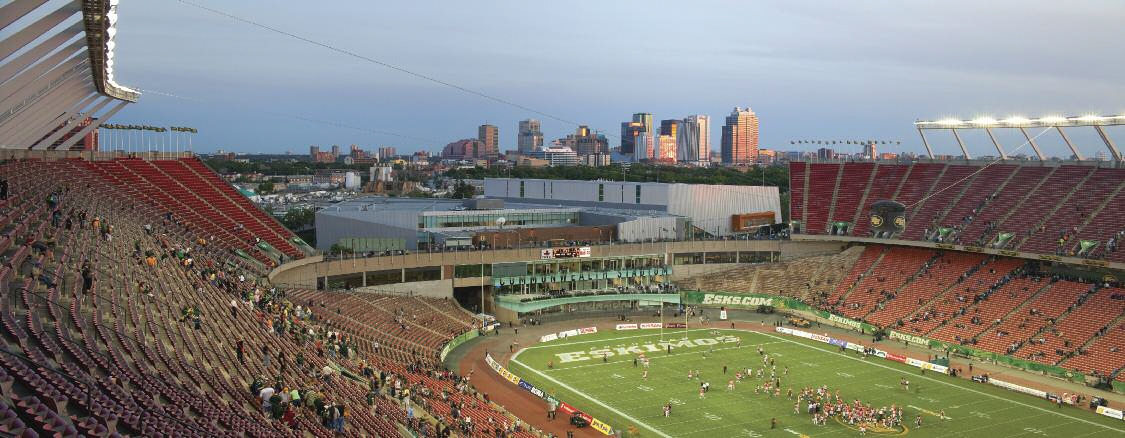

MJMA of Toronto along with local partners HIP Architects (now Kasian) built on and expanded the formerly underutilized site of the 1978 Commonwealth Stadium, cleverly combining: stadium activities, football operations, and a fitness and community centre. The integrated facility was designed to allow three diverse partner groups to share their program specific amenities. Co-locating these amenities unlocked site synergies, enhancing benefits and revenues while the parklike configuration has helped reinvigorate the community.

The CCRC was envisioned as three masses – gymnasium, aquatics, and field house – combined into one. The field house was slated to be open in time for the November 2010 Grey Cup Championships, which necessitated phased construction to a fast track schedule. Clark Builders and structural engineers RJC proposed long span spoke steel trusses, prioritizing local fabrication and delivery to stay on schedule and within the tight city budget. Moving full speed ahead with the steel design allowed the team to get a jump on the field house, the first project out of the blocks.

The three masses define the building’s structure, whose dynamic angular geometry and bold steel rooflines provide a striking counterpoint to the monolithic concrete bowl. MJMA Principal Ted Watson, describes: “We wanted the building to read at the same scale as the stadium. We let the formal aspect – the shape – be the key feature. And the steel cladding lent itself because it’s a uniform, continuous materiality that allowed the formal qualities to be really clear.”

A façade clad with .91mm (.036”) pre-painted Z275 (G90) galvanized standing seam steel siding coloured QC2624 Bright Silver, begins at grade and slants upwards to form a canopy above the main entrance. Steel cladding is often a default material for large buildings due to its versatility, flexibility, and lightweight nature. And because of its cost effectiveness, the architects, who favour a limited material palette, were able to wrap it around the entire complex. Making this typically austere, utilitarian material special, however, is a challenge MJMA and HIP met with confidence. “There’s a humility and pride to this industrial language of buildings,” says Watson. “Our job is to elevate these commonplace materials so they have a civic presence by giving attention to how the material is expressed, its detailing and execution.” Other materials include ceramic-fritted glazing and a tessellated phenolic wood panel system at canopy and window openings.

A large cladding mock-up on site enabled the team to resolve the most intricate transition points: soffit, parapet, and corner details. MJMA worked with the cladding manufacturer and installer to develop a potentially minor but perhaps critical detail: the soffit panel termination. By folding the 300 – 400mm (11.8” – 15.75”) wide panel back over the parapet, the need for a cap was avoided. Allowing the vertical seams to complete at the top lends a more abstract quality. While tried and true is a lower risk proposition, MJMA uses the cladding in a different way on each project, developing it in a way that is more interesting or innovative in approach to its materiality use.

And the pre-painted .91mm (.036”) Z275 (G90) galvanized steel cladding continues into the interior. In the field house, for instance, a prefinished white steel liner negates the need for furring out and operates as a vapour retarder. Two layers of double strapped insulation reduce thermal bridging, which can be an issue in Edmonton’s climate. An additional benefit of a unified cladding system is the complete envelope stays with one sub-trade.

DESIGN AND CONSTRUCTION TEAM:

OWNER: City of Edmonton

ARCHITECT: MacLennan Jaunkalns Miller Architects (MJMA)

ASSOCIATED ARCHITECT: HIP Architects (now Kasian)

STRUCTURAL: Read Jones Christoffersen Engineering

MECHANICAL & ELECTRICAL: Hemisphere Engineering

CONSTRUCTION MANAGER: Clark Builders

INTERIOR DESIGN: MJMA

STRUCTURAL STEEL SUPPLIERS:

– Collins Industries – Fieldhouse, Eskimos’ Office and Team Rooms

– Whitemud Ironworks – Multi-use Recreational Centre

STRUCTURAL STEEL INSTALLER: Clark Builders

WALL CLADDING SUPPLIER: Vicwest

WALL CLADDING INSTALLER: Clark Builders

PHOTOGRAPHERS: Tom Arban and Jim Dobie