DIYers Use Steel to Build Decks as Lumber Prices Soar

Most people are spending more time at home these days. As a result, there has been a surge in do-it-yourself home improvement projects.

A recent Porch.com survey found:

- 76% of homeowners have completed at least one home improvement project since the coronavirus shutdown occurred in the U.S.

- 78% plan to complete a project over the next year.

- 61% of homeowners worked on their garden or patio, or they renovated the structure of their house.

DIY Projects Lead to Wood Price Shock

Houzz reports that 1 in 8 homeowners funnelled their energy into a complete deck overhaul during the past year.

According to The Garden Island, a deck addition maximizes usable square footage by extending the living area beyond the indoors. When it comes time to sell a home, deck renovations can recoup up to 90% of their cost, according to HGTV’s Top 15 Home Updates.

But, most homeowners were in for a shock when they went to their local lumber supply store and either could not find pressure treated lumber — or were forced to pay exorbitant prices.

Jason Larabee, the owner of a building supply shop in Vermont, typically pays 80 cents per board foot for treated wood. In late summer, that cost more than doubled to $1.80, according to VTDigger. The wholesale cost hikes have forced Larabee to raise his prices.

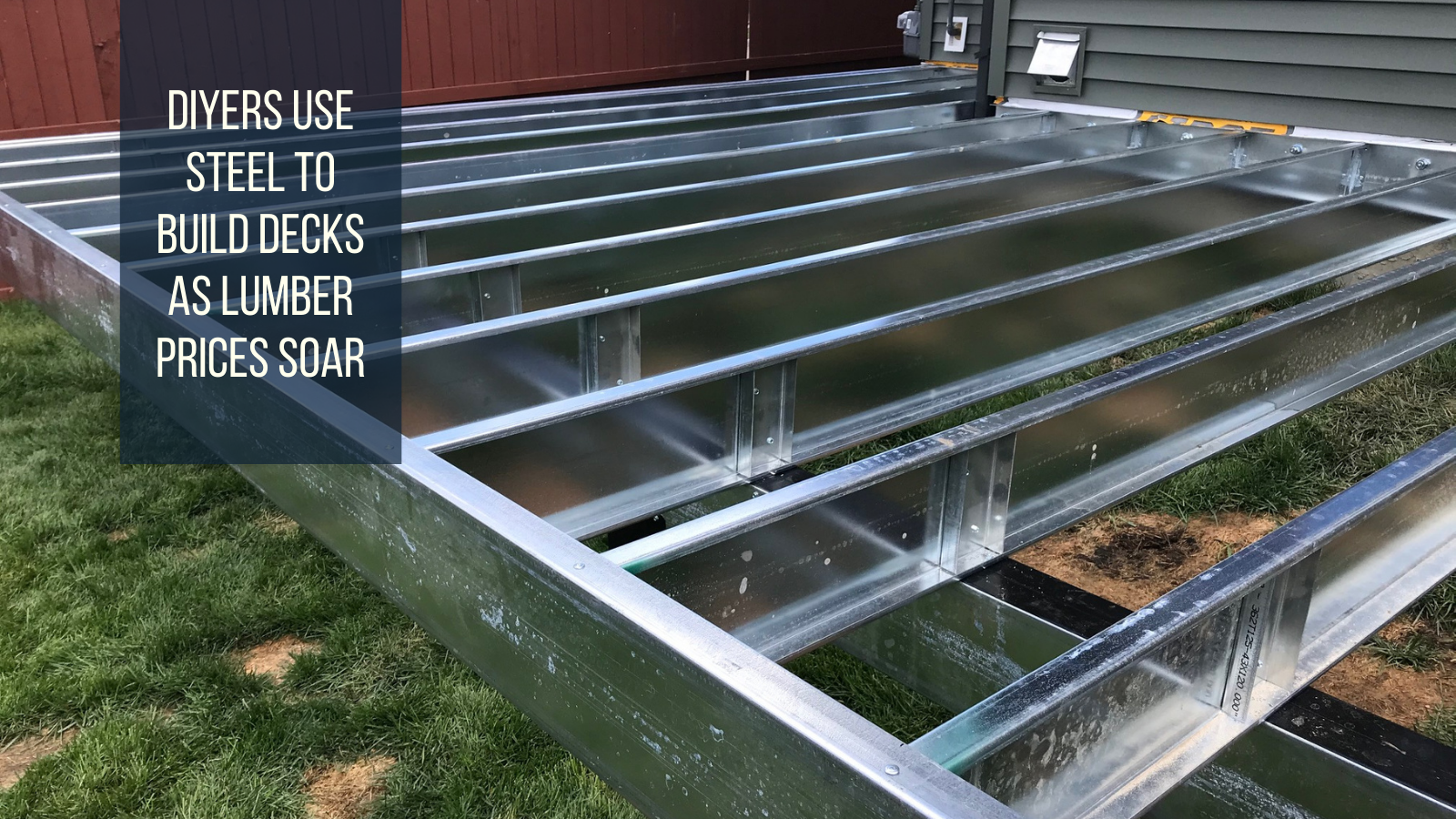

Steel Saves the Day

At one time, lumber was the only framing product available to build decks. However, since lumber typically starts deteriorating after 10 years in service, VTDigger says builders and homeowners are turning to steel as an alternative.

Cold-formed steel (CFS) framing is now being used to create durable and sustainable outdoor living spaces. Homeowners appreciate steel’s lower cost, availability and long-term durability. It’s a win-win situation for today’s DIYers.