Project Profile: Park City - Winnipeg, Manitoba

This 82,000sf - 6 story apartment building is located in the suburbs of Winnipeg, Manitoba and was constructed in 2019 by Light-weight Building Systems Inc. Substantial completion was achieved on December 31st, 2019.

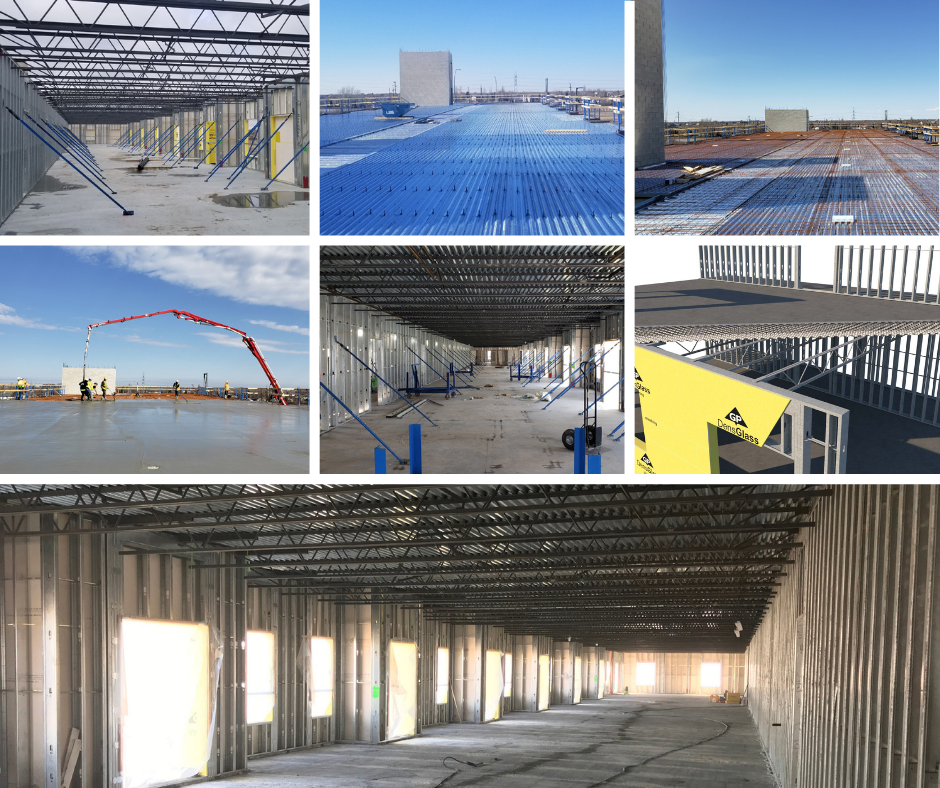

Light-weight Building Systems Inc. engineered, supplied and installed all load bearing steel stud LBS wall panels, structural steel along with the floor and roof system components.

Installations on the ground floor started on March 1st, 2019 and the superstructure was complete by mid June. Delivered on time with a successful 14 week schedule.

Challenge #1

Winter conditions in Winnipeg were a concern that Light-weight Building Systems Inc. prepared for as the preliminary site schedule had them starting installations in February or early March.

They provided their load bearing exterior wall panels with exterior sheathing pre-installed and they ran through some of the window and door openings.

The openings that were not sheathed over were temporarily sealed with tarpaulin, easily installed in the field or at the panel plant.

This combination of sheathing and tarpaulin acted as hoarding for the slab pours and was removed soon after.

Challenge #2

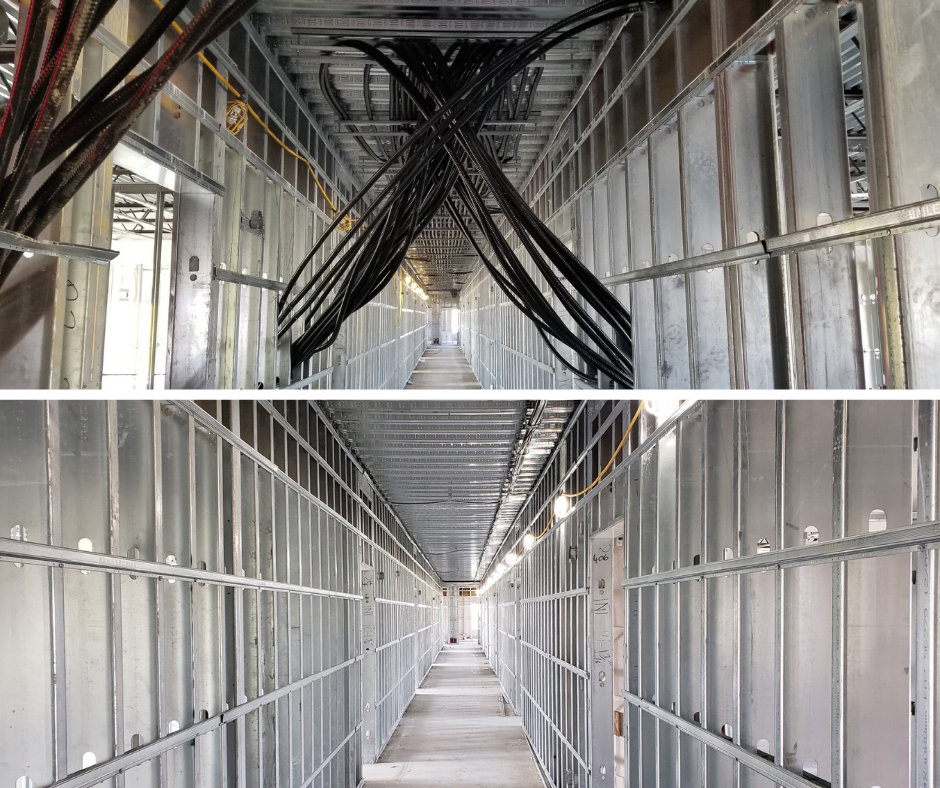

The building's design called for a variety of approaches to the suspended floor construction. The main floor above the parkade was a concrete hollow core slab while the second floor through level six was a mix of composite joist and 1” decking above the suites, 2” decking in the corridor, and precast concrete slabs for the balconies.

LBS proposed the EcoSpan floor system supplied by Nucor as the composite assembly and integrated this with the design of the corridor decking and precast balcony approach.

LBS provided 3D modelling to coordinate all wall, floor and roof components with the Architectural, Mechanical and Structural requirements. The structure came together great.

Challenge #3

The precast concrete balcony slabs were designed to connect to the floor level slab edges.

LBS provided a perimeter slab edge structural angle, typically used in all their designs, to facilitate the attachment of the balconies.

This structural angle is fastened to the tops of the load bearing walls and acts as a concrete pour stop and also provides the perfect weld plate for attaching items such as shelf angles and brick ledger angles.

The precast balconies were installed to shelf angle clips after the structure was erected. This sequencing of the balcony installation after the main structure allowed for critical path items to progress without delay.

Results, Return on Investment and Future Plans

Throughout the engineering, 3D modelling, detailing, fabrication and installation of this superstructure, Light-weight Building Systems Inc. found ways to coordinate all the requirements of the buildings design while maintaining a tight schedule.

The LBS System provided a non-combustible building that will save the owner considerably over the lifespan of its use. It is also important to note that this building will retain its value and maintenance issues will be reduced compared to a wood frame due to its inherent quality by using Bailey Metal Products Limited steel studs that do not warp, shrink, twist or provide an environment for mold or insects to thrive.